101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-18028142339 [email protected]

101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-18028142339 [email protected]

In the current fierce market competition, cost control is the key for enterprises to enhance their competitiveness. Our company's wire forming equipment has brought significant cost advantages to enterprises through optimization in multiple aspects, achieving a win-win situation of cost reduction and efficiency improvement.

From the perspective of labor costs

Traditional wire processing relies on a large amount of manual operations, which is not only inefficient but also incurs high labor costs. Our series of wire forming equipment has achieved a high degree of automation, significantly reducing reliance on manual labor.

• The chasing and cutting straightening machine automatically completes the straightening and cutting of wires without manual intervention.

• The automatic coiling machine is easy to operate—"anyone who knows 1, 2, 3 can get started"—allowing one worker to operate multiple devices simultaneously.

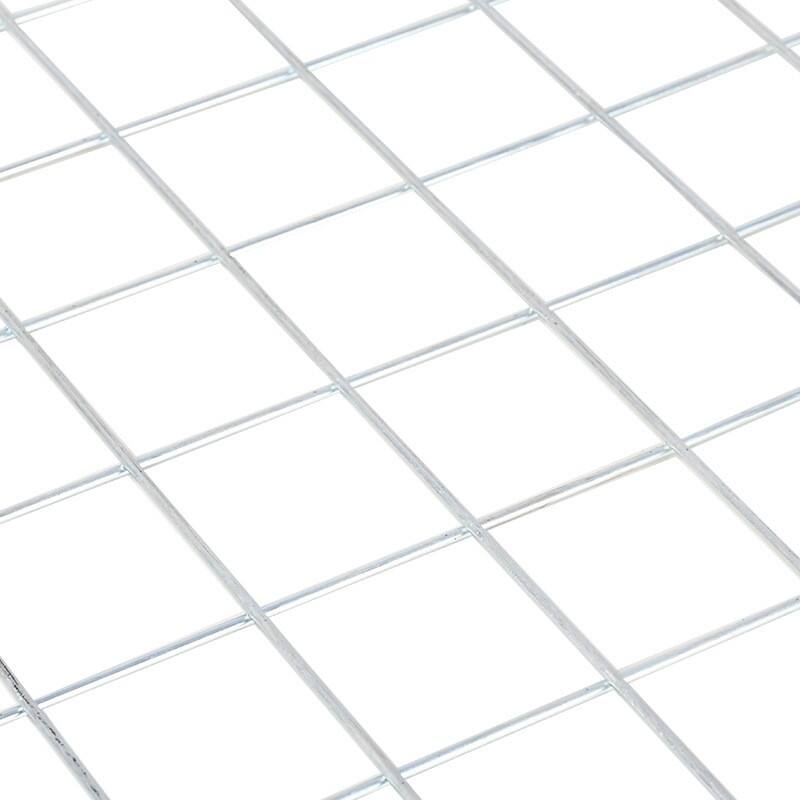

• Welding equipment such as gantry welders and wire mesh row welders realize fully automatic welding, replacing traditional manual welding and reducing the demand for skilled welders.

Taking the production of breeding chicken cage mesh as an example, a fully automatic production line only requires 2-3 workers to monitor equipment operation, while traditional manual production requires 8-10 workers, reducing labor costs by more than 60%.

Savings in raw material costs are also considerable

The high-precision processing of the equipment reduces the waste of raw materials:

• The chasing and cutting straightening machine controls the wire cutting error within ±0.3mm, avoiding wire waste caused by inaccurate length.

• The coiling and butt welding integrated machine precisely controls the coil diameter with a perimeter tolerance of ±0.3mm, ensuring that each coil of wire is fully utilized.

• The high-precision bending of 2D and 3D wire bending machines reduces waste products caused by forming errors and improves the utilization rate of raw materials.

Statistics show that using our company's wire forming equipment can reduce the waste rate of raw materials by about 30%. For enterprises with large-scale production, this can save a substantial amount of raw material costs every year.

The efficient operation of the equipment also reduces the energy consumption cost per unit product

Equipment such as automatic coiling machines and buckle machines adopt advanced control systems, which can accurately adjust energy consumption according to processing needs, avoiding unnecessary energy waste. At the same time, the continuous and stable operation of the equipment reduces energy loss caused by frequent start-ups and shutdowns.

Taking the coiling and butt welding integrated machine as an example, its energy consumption per unit product is reduced by more than 20% compared with traditional equipment. Long-term use can save enterprises a considerable amount of energy costs.

In addition, the durability of the equipment reduces the maintenance and replacement costs for enterprises

Key components of the flattening machine undergo precision grinding and heat treatment, greatly extending their service life. Welding equipment uses high-quality servo systems and welding components, resulting in low failure rates and reduced maintenance costs.

The long service life and low failure rate of these devices reduce the downtime and expenses incurred by enterprises due to equipment repair and replacement, further enhancing their economic benefits.

Hot News

Hot News2026-02-02

2026-01-08

2025-07-25

2025-06-19

2025-05-11