101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-18028142339 [email protected]

101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-18028142339 [email protected]

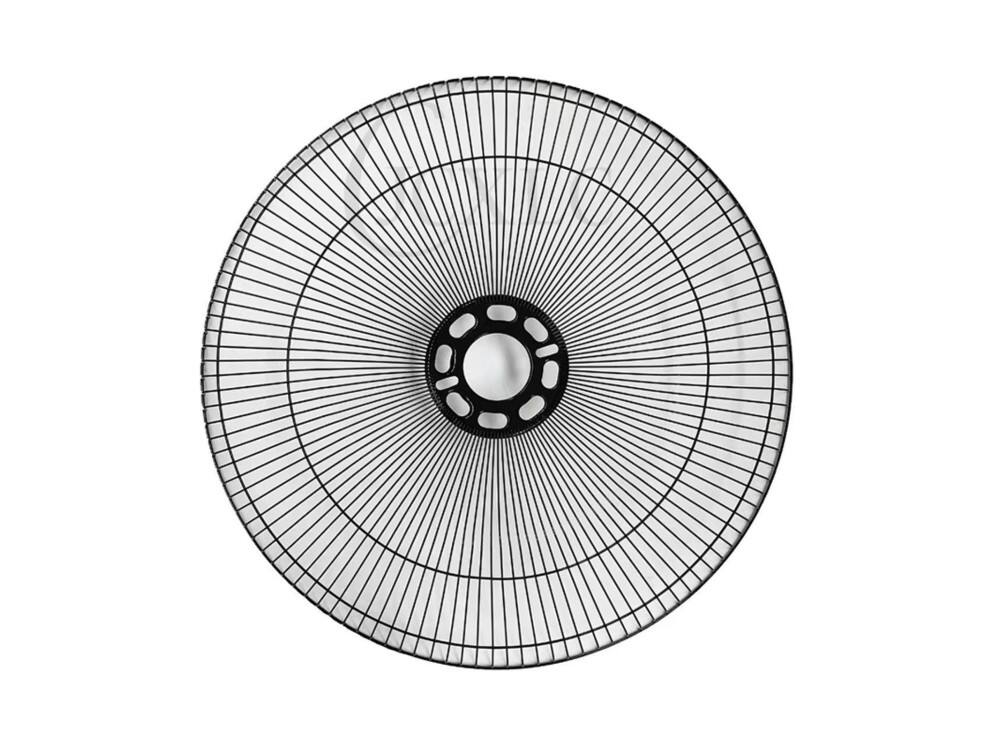

Equipped with flexible process adjustment capabilities, it can quickly switch production modes according to different guard styles (such as round, square, and special-shaped). It supports diversified processing of wire materials—whether iron wire, stainless steel wire, or galvanized wire, it can achieve stable processing. This meets customers' personalized needs for the appearance, strength, and other properties of the guard, enhancing the market competitiveness of the product.

It can quickly switch cage sizes and structures through program settings, supporting the production of various styles such as single-door, double-door, and foldable ones. Equipped with an intelligent control system, it can call preset parameters with one click, shortening the production changeover time to within 10 minutes, and flexibly meeting the order requirements of small batches and multiple varieties.

It integrates processes such as wire cutting, frame welding, and accessory assembly, realizing the continuous production of shopping carts from raw materials to finished products. It is suitable for shopping cart specifications in different scenarios such as supermarkets and shopping malls, with high welding strength, assembly accuracy up to ±1mm, and production efficiency 60% higher than that of traditional processes.

Integrating wire bending, grid welding and edge grinding, it realizes the automatic production of disinfection bowl baskets from raw materials to finished products. It is suitable for different specifications of built-in and desktop disinfection cupboards, with uniform grid spacing, and the production efficiency is 50% higher than that of traditional processes.