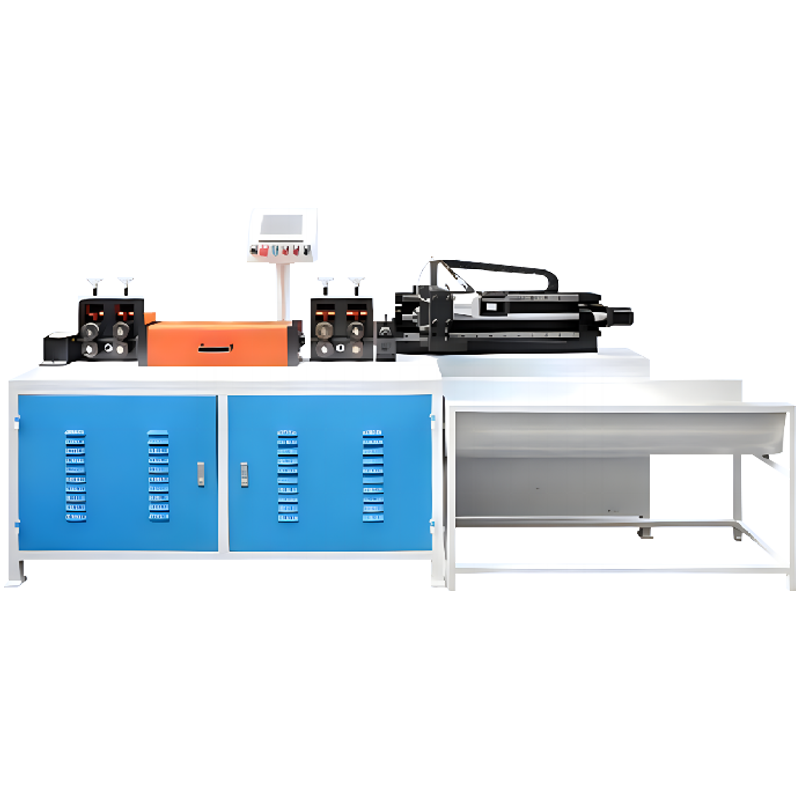

In the manufacturing of metal mesh and grid structures, the quality of the base material is critical. Precision-cut and perfectly straightened metal bars or wires form the essential backbone for a wide range of industrial applications. For manufacturers processing round or flat bars, modern straightening and cutting machines have become indispensable, integrating high speed, exceptional accuracy, and remarkable flexibility to efficiently produce flawless straight strips. The key to this outstanding performance lies in the deep integration of advanced mechanical engineering and intelligent control systems.

Core Mechanism: Achieving Top-Tier Precision of ±0.02mm

The ultra-high accuracy is derived from a meticulously calibrated mechanical system guided by smart technology. The process involves feeding material through a series of adjustable straightening rollers to eliminate all bends and twists, followed by precise cutting. The critical cutting length accuracy of ±0.02 mm is accomplished thanks to servo-driven feeding systems and high-resolution encoders that monitor the material's exact position and speed in real-time.

Our machine series is designed to handle various materials (such as iron, stainless steel, aluminum, copper) across a broad diameter range, meeting diverse production needs:

Universal Model: Suitable for materials with a 1–16 mm diameter, operating at a speed of 25–35 meters per minute.

High-Speed Model: Optimized for 1–7 mm diameter materials, achieving speeds of 80–130 meters per minute, ideal for high-volume production.

Heavy-Duty Model: For processing thicker materials with a 2–20 mm diameter, running at 35–55 meters per minute, delivering robust power.

All models are equipped with a universal quick-change die system, allowing operators to switch between different material sizes or shapes with minimal downtime, ensuring consistent straightening results across various tasks. Specially hardened or coated rollers effectively prevent surface scratches, guaranteeing smooth, burr-free output.

Intelligent Operation and Unmatched Flexibility

Ease of use is central to achieving stable output quality. Each machine features a multi-language intelligent control system with both button and touchscreen operation, enabling even beginners to become proficient within 30 minutes. Operators simply need to input basic parameters such as diameter, length, and quantity, and the system automatically configures the machine.

The wide cutting length range from 45 mm to 8 meters offers tremendous flexibility for diverse production requirements, eliminating the need for secondary processing. Furthermore, the machines support integrated custom functions like punching, flattening, or dot marking, enabling multiple operations in a single pass. This not only significantly adds value but also ensures the precise positioning of added features.

Built for Superior Quality and Long-Term Reliability

Consistent precision relies on robust mechanical construction and a rigorous quality assurance system. These machines are designed for long service life, with an average lifespan exceeding 10 years and an annual failure rate below 3%. Their exceptional reliability stems from high-quality core components, a rigid and stable frame, and precision-ground guideways.

Every unit undergoes strict Quality Control (QC) inspection and is CE certified before shipment, ensuring full compliance with international safety and performance standards. The comprehensive focus on quality control guarantees that every straight bar produced is ready for subsequent processes like welding or assembly without any need for additional treatment.

Comprehensive Support Ensuring Sustained High Efficiency

Choosing precision equipment also means gaining our firm commitment to customer service. We provide an average after-sales response time of under 2 hours and offer a 1-year warranty period. The intelligent system also assists with preventive maintenance reminders, helping to ensure uninterrupted production and maximize productivity throughout the machine's extended lifecycle.

Conclusion

Our straightening and cutting machines represent the perfect fusion of mechanical precision engineering and digital control technology. By delivering ±0.02 mm extreme accuracy, a wide speed range, rapid die changeover capability, and a user-friendly intelligent operation experience, they provide a complete, one-stop solution for producing straight, clean, and dimensionally precise materials. This ensures that manufacturers can continuously enhance product quality, reduce material waste, and significantly improve overall production efficiency in their wire and bar processing operations.