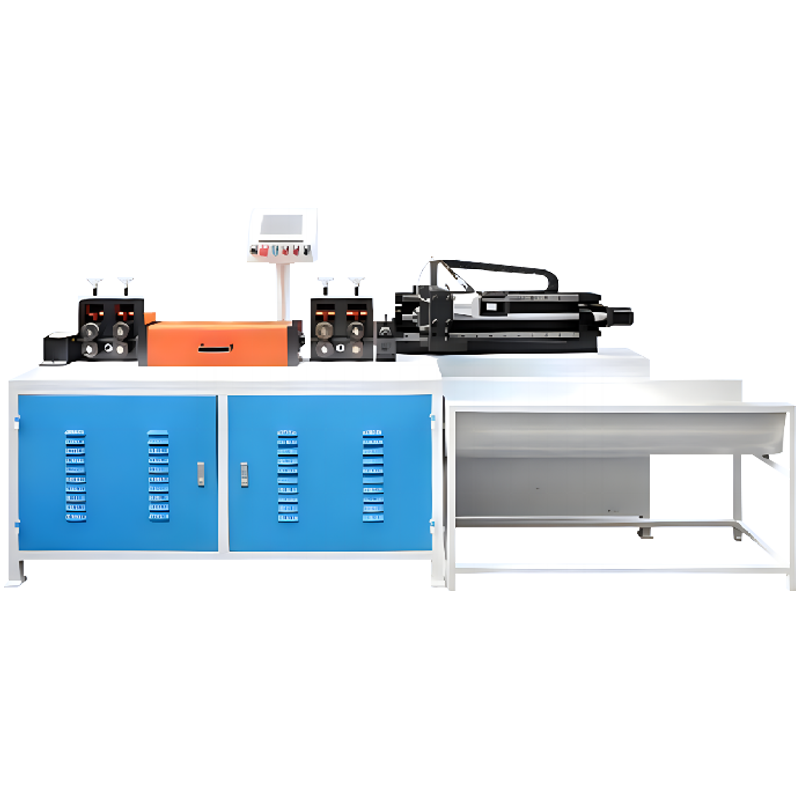

Manufacturing industries rely heavily on precise wire processing equipment to maintain product quality and operational efficiency. When wire materials arrive coiled or bent from suppliers, achieving the straightness required for downstream applications becomes a critical challenge. A wire straightening machine serves as an essential solution for transforming curved or coiled wire into perfectly straight lengths, enabling manufacturers to meet strict dimensional tolerances and quality standards across various industrial applications.

The selection process for wire straightening equipment involves multiple technical considerations that directly impact production outcomes. Wire diameter capacity, processing speed, material compatibility, and precision requirements must align with specific manufacturing needs. Understanding these fundamental parameters helps procurement teams make informed decisions that optimize both initial investment costs and long-term operational performance.

Modern wire straightening technology has evolved significantly, incorporating advanced roller systems, servo-driven mechanisms, and automated control features. These improvements deliver superior straightness accuracy while reducing manual intervention requirements. Manufacturers who invest in appropriate straightening equipment often experience improved downstream processing efficiency, reduced material waste, and enhanced final product quality.

Understanding Wire Straightening Technology

Mechanical Straightening Principles

Wire straightening operates on the principle of controlled bending and stress relief through multiple contact points. The wire passes through a series of precisely positioned rollers or dies that apply calculated pressure to eliminate inherent curvature and memory effects. Each roller pair applies specific force vectors that counteract the wire's natural tendency to return to its coiled state.

The effectiveness of mechanical straightening depends on proper roller positioning, adequate pressure distribution, and appropriate feed speeds. Engineers must consider the wire's material properties, including yield strength, elastic modulus, and work hardening characteristics, when configuring roller systems. Optimal straightening occurs when applied forces exceed the material's elastic limit without causing permanent deformation or surface damage.

Advanced straightening systems employ multiple roller stages with progressively refined adjustments to achieve superior results. Initial stages handle gross straightening requirements, while subsequent stages fine-tune dimensional accuracy and surface finish quality. This staged approach minimizes stress concentrations and prevents work hardening issues that could compromise wire integrity.

Roller Configuration Systems

Traditional roller-based systems utilize opposing roller pairs arranged in alternating vertical and horizontal orientations. This configuration ensures comprehensive straightening across all directional axes while maintaining consistent wire guidance throughout the process. Roller materials typically include hardened steel, tungsten carbide, or ceramic composites selected for durability and wear resistance.

Roller spacing and diameter specifications must match the intended wire diameter range for optimal performance. Insufficient roller contact can result in incomplete straightening, while excessive pressure may cause surface indentations or dimensional distortion. Manufacturers often provide adjustable roller systems that accommodate multiple wire sizes within specified diameter ranges.

Precision roller systems incorporate micro-adjustment capabilities that enable operators to fine-tune straightening parameters for specific material types. These adjustments account for variations in wire hardness, surface conditions, and straightness requirements across different production batches. Regular roller maintenance and replacement schedules ensure consistent performance throughout equipment service life.

Key Selection Criteria

Wire Diameter Compatibility

Diameter capacity represents the primary specification defining a wire straightening machine's operational envelope. Equipment manufacturers typically design systems for specific diameter ranges, with common categories including fine wire (0.1-2.0mm), medium wire (2.0-8.0mm), and heavy wire (8.0-20.0mm) applications. Selecting equipment with appropriate diameter capacity ensures optimal performance and prevents premature wear or mechanical stress.

The relationship between wire diameter and required straightening force follows exponential scaling patterns. Larger diameter wires demand significantly higher straightening forces and more robust mechanical systems. Attempting to process oversized wire through undersized equipment results in incomplete straightening, excessive roller wear, and potential machine damage.

Variable diameter capability provides operational flexibility for manufacturers handling multiple wire sizes. Adjustable roller systems and quick-change tooling reduce setup times when transitioning between different wire specifications. However, universal systems may compromise precision compared to dedicated single-diameter equipment, requiring careful evaluation of application priorities.

Processing Speed Requirements

Production throughput demands directly influence speed requirements for wire straightening equipment. High-volume manufacturing operations require machines capable of processing hundreds of meters per minute while maintaining dimensional accuracy. Processing speed capabilities vary significantly across equipment categories, from basic manual units operating at 10-20 meters per minute to automated systems achieving speeds exceeding 200 meters per minute.

Speed limitations often arise from wire material properties rather than machine capabilities. Harder materials require slower processing speeds to achieve complete stress relief and dimensional stability. Conversely, softer materials can typically withstand higher processing speeds without compromising straightening quality or surface finish characteristics.

Balancing speed with quality requirements involves understanding the relationship between processing parameters and final product specifications. Higher speeds may reduce per-unit processing costs but could compromise dimensional tolerances or surface quality. Manufacturers must evaluate production volume requirements against quality standards to determine optimal speed specifications for their applications.

Material Compatibility Considerations

Steel Wire Applications

Steel wire represents the most common material processed through straightening equipment, encompassing carbon steel, stainless steel, and alloy steel varieties. Each steel type exhibits unique mechanical properties that influence straightening requirements and equipment selection criteria. Carbon steel wires typically demonstrate predictable straightening behavior with standard roller configurations and processing parameters.

Stainless steel applications present additional challenges due to work hardening characteristics and higher yield strength values. These materials often require specialized roller materials, reduced processing speeds, and enhanced cooling systems to prevent overheating during straightening operations. Equipment selection must account for the increased mechanical loads and potential tool wear associated with stainless steel processing.

Alloy steel wires containing chromium, nickel, or other alloying elements may exhibit unpredictable straightening behavior requiring customized processing parameters. Material certificates and mechanical property data help engineers establish appropriate straightening settings and predict equipment performance for specific alloy compositions.

Non-Ferrous Metal Processing

Aluminum, copper, and brass wires present unique straightening challenges compared to steel materials. These non-ferrous metals typically exhibit lower yield strength and higher ductility, requiring reduced straightening forces and modified roller configurations. Excessive pressure during straightening can cause permanent deformation or surface marking that compromises final product quality.

Copper wire straightening applications often involve electrical conductor manufacturing where surface quality and dimensional precision directly impact electrical performance. Wire straightening machine systems designed for copper processing incorporate specialized roller materials and surface treatments that minimize scratching or contamination risks.

Temperature considerations become critical when processing non-ferrous materials due to their thermal sensitivity and potential for work hardening. Cooling systems and temperature monitoring capabilities help maintain optimal processing conditions and prevent material property changes during straightening operations.

Precision and Quality Standards

Dimensional Tolerance Requirements

Manufacturing applications demand specific straightness tolerances that vary according to end-use requirements and industry standards. Precision applications such as medical device components or aerospace assemblies may require straightness tolerances within 0.1mm per meter, while general construction applications might accept tolerances of 2-3mm per meter. Understanding tolerance requirements guides equipment selection and processing parameter optimization.

Straightness measurement techniques include laser-based systems, mechanical gauging, and coordinate measuring machines that provide quantitative assessment of dimensional accuracy. Modern wire straightening machine systems often incorporate inline measurement capabilities that enable real-time process monitoring and automatic adjustment of straightening parameters.

Statistical process control methods help manufacturers maintain consistent quality levels while identifying trends that might indicate equipment wear or process drift. Regular calibration and measurement system validation ensure measurement accuracy and support continuous improvement initiatives.

Surface Quality Preservation

Surface finish requirements significantly influence roller material selection and processing parameter optimization. Applications requiring pristine surface conditions demand specialized roller coatings, reduced contact pressures, and enhanced lubrication systems. Surface defects introduced during straightening operations can compromise downstream processing or final product performance.

Roller wear patterns and replacement schedules directly impact surface quality consistency throughout production runs. Predictive maintenance programs monitor roller condition through surface roughness measurements, dimensional checks, and visual inspections. Proactive roller replacement prevents surface quality degradation and maintains consistent product specifications.

Lubrication systems reduce friction between wire and rollers while preventing surface contamination or marking. Appropriate lubricant selection considers material compatibility, environmental regulations, and downstream cleaning requirements. Some applications require dry processing to eliminate contamination risks, necessitating specialized roller materials and surface treatments.

Automation and Control Features

Programmable Control Systems

Modern wire straightening equipment incorporates programmable logic controllers and human-machine interfaces that simplify operation and enhance repeatability. These control systems store processing parameters for different wire specifications, enabling rapid changeovers and consistent quality across production batches. Operator training requirements decrease significantly when intuitive control interfaces replace manual adjustment procedures.

Recipe management capabilities allow operators to store, recall, and modify processing parameters for specific wire types and quality requirements. Advanced systems include parameter optimization algorithms that automatically adjust straightening settings based on real-time feedback from measurement systems or quality monitoring equipment.

Integration capabilities with enterprise resource planning systems and manufacturing execution systems enable data collection and analysis for continuous improvement initiatives. Production reporting, quality tracking, and preventive maintenance scheduling become automated functions that reduce administrative overhead while improving operational visibility.

Safety and Monitoring Systems

Comprehensive safety systems protect operators and equipment from potential hazards associated with high-speed wire processing. Emergency stop systems, safety interlocks, and protective guards prevent accidental contact with moving components while enabling rapid shutdown during emergency conditions. Regular safety system testing and documentation support regulatory compliance requirements.

Monitoring systems track critical operating parameters including motor loads, temperatures, vibration levels, and processing speeds. Alarm systems alert operators to abnormal conditions that might indicate impending equipment failure or quality issues. Predictive maintenance capabilities analyze trend data to schedule maintenance activities before failures occur.

Remote monitoring capabilities enable technical support teams to provide assistance and diagnostic services without on-site visits. Internet connectivity and secure data transmission protocols facilitate troubleshooting and performance optimization while maintaining cybersecurity standards required in modern manufacturing environments.

Economic Considerations

Initial Investment Analysis

Equipment acquisition costs vary significantly based on capacity, automation level, and precision requirements. Basic manual systems suitable for low-volume applications start around $10,000-$20,000, while fully automated high-precision systems can exceed $100,000. Total cost of ownership analysis should include installation, training, and commissioning expenses beyond base equipment pricing.

Financing options including leasing, rental, and equipment loans provide alternatives to outright purchase that may better align with cash flow requirements and tax planning strategies. Equipment suppliers often provide financing assistance or partnerships with equipment finance companies to facilitate acquisition decisions.

Return on investment calculations should consider labor savings, quality improvements, and waste reduction benefits achievable through automated straightening systems. Quantifying these benefits requires analysis of current manual processes, labor costs, and quality-related expenses including rework and customer returns.

Operating Cost Factors

Ongoing operational costs include electrical consumption, maintenance supplies, replacement parts, and periodic service requirements. Energy-efficient motor systems and optimized processing parameters minimize electrical costs while maintaining production throughput. Regular maintenance schedules prevent costly emergency repairs and extend equipment service life.

Roller replacement represents the primary consumable expense for wire straightening equipment. Roller life depends on processed wire types, production volumes, and operating conditions. Higher-quality roller materials and coatings provide extended service life but require higher initial investment. Cost analysis should evaluate roller cost per unit processed rather than absolute replacement costs.

Training and support costs affect long-term operational success and should be evaluated during equipment selection. Comprehensive training programs reduce operator errors and improve equipment utilization rates. Technical support availability and response times impact production continuity during equipment issues or optimization requirements.

FAQ

What wire diameter range can a typical wire straightening machine handle

Most commercial wire straightening machines are designed for specific diameter ranges rather than universal compatibility. Common categories include fine wire systems handling 0.1-2.0mm diameters, medium wire systems for 2.0-8.0mm ranges, and heavy wire systems accommodating 8.0-20.0mm or larger diameters. Some adjustable systems can handle ranges spanning 2-3mm variation, but dedicated systems typically provide better precision and performance for specific diameter requirements.

How do I determine the appropriate processing speed for my application

Processing speed selection depends on wire material properties, required straightness tolerance, and production volume requirements. Harder materials like stainless steel typically require slower speeds (10-50 meters per minute) for complete stress relief, while softer materials like aluminum can often be processed at higher speeds (50-200+ meters per minute). Applications requiring tight straightness tolerances may need reduced speeds regardless of material type to achieve optimal results.

What maintenance requirements should I expect with wire straightening equipment

Regular maintenance includes roller inspection and replacement, lubrication system service, alignment checks, and control system calibration. Roller replacement frequency depends on processed wire types and production volumes, typically ranging from weekly to monthly intervals. Preventive maintenance programs should include motor bearing service, safety system testing, and measurement system verification to ensure consistent performance and regulatory compliance.

Can one machine handle multiple wire materials and sizes

While some adjustable systems can accommodate multiple wire sizes within specified ranges, material compatibility depends on mechanical property similarities rather than dimensional compatibility alone. Processing different materials may require roller changes, parameter adjustments, and potentially different lubrication systems. Multi-material capability typically involves trade-offs in precision or processing speed compared to dedicated single-material systems, requiring careful evaluation of application priorities and production requirements.