101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-18028142339 [email protected]

101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-18028142339 [email protected]

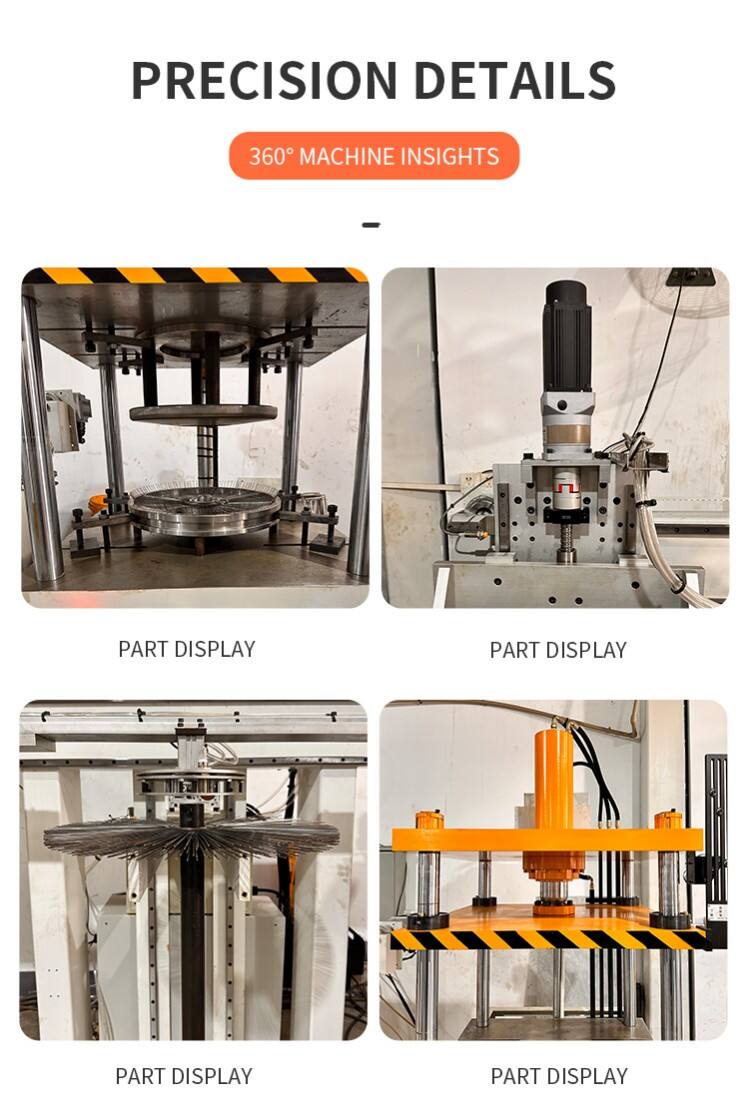

Our Hydraulic Press Machine is a robust wire forming equipment designed for heavy-duty wire pressing and shaping, suitable for wire diameters up to 16mm

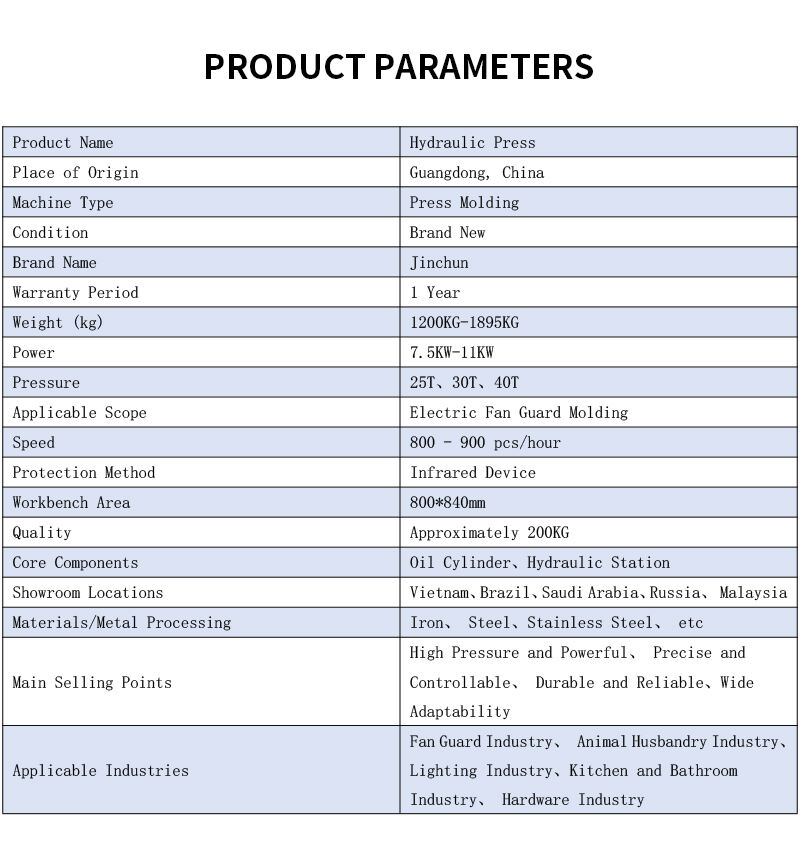

| Industry basic attributes | 25T | Product custom attributes | |

| Machine type | Four-column Three-beam Hydraulic Press | Product Name | 25T Hydraulic Press |

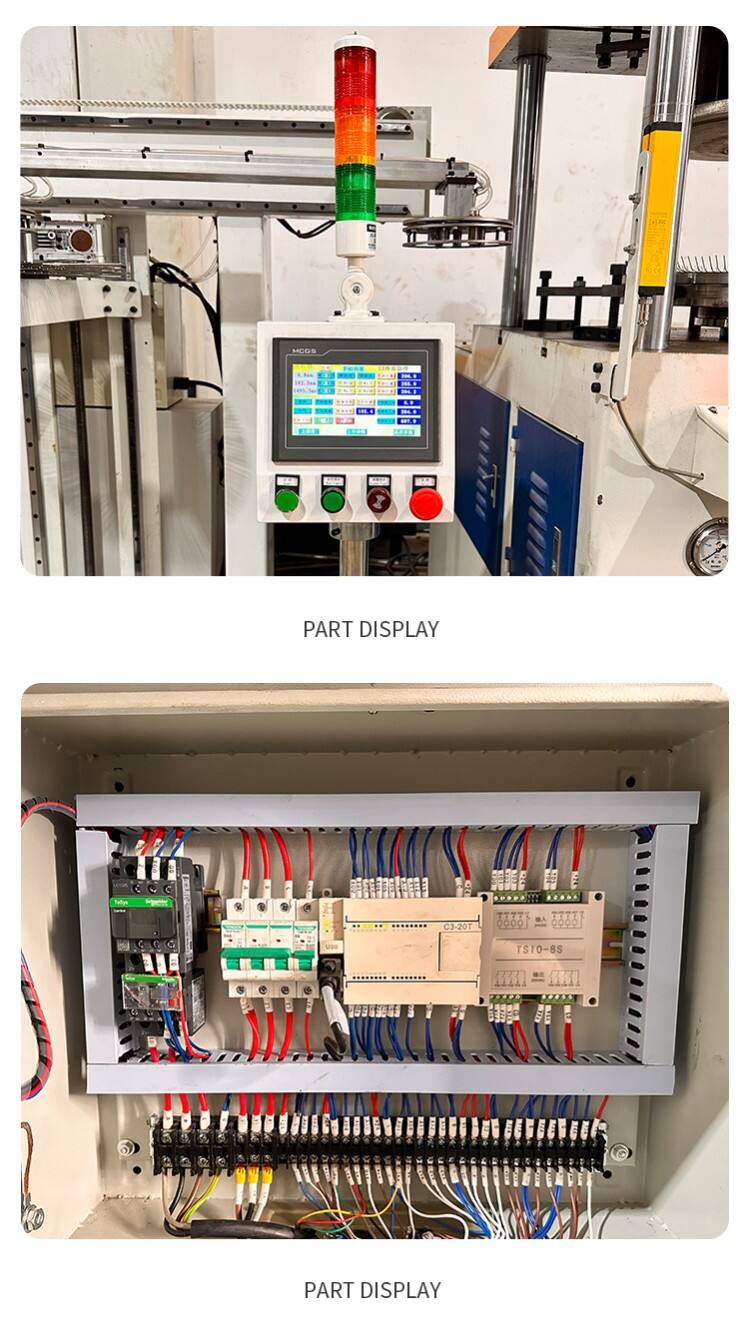

| System | Normal | Current | 30-40A |

| Voltage | 380V | Platform square | 850*850mm |

| Weight (tons) | 1.5T | Speed | 800-900pcs |

| Motor power (KW) | 7.5KW | Protection | Infrared ray device |

| Warranty period | 1 Year | Pressure | 25T |

| Core component | Motor,Pump,Gear,Pressure vessel | Oil Pump | PV2R1-28 |

| Slider stroke (mm) | 350 | Upper cylinder bore diameter | 140mm |

| Top force (KN) | 55 | Upper cylinder pressing stroke | 350mm |

| Return force (KN) | 25 | Lower ejector cylinder bore diameter | 80mm |

| Dimensions (length * width * height) | 1600*1000*2500mm | Hydraulic pump motor power | 7.5KW |

| Model | 25T | Certification | CE |

| Core selling point | Multifunctional、Easy to Operate、High Productivity | Type | Manual Bending Machine |

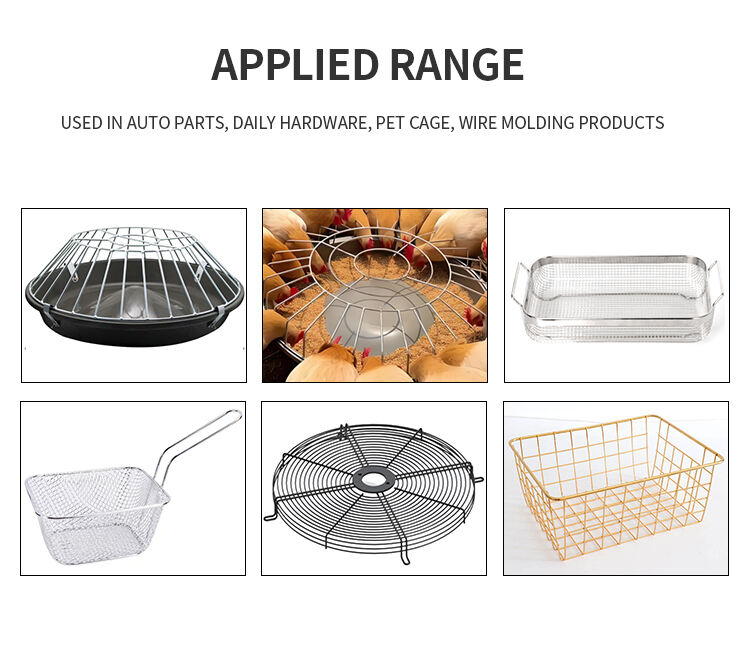

| Mechanical test report | Provided | Suitable for | Fan Guard/Bird Cage/Super Market Cart |

| Video factory inspection | Provided | Transport Package | Sea Worthy Wooden Package or PVC Film for FCL |

| Is it customizable | Can be customized | ||

| Logistics attribute | Volume and weight (including logistics packaging) | ||

| Gross weight (KG) : 1881KG | Length (mm) : 1450 | Width (mm) : 1100 | Height (mm):2200 |

Our Hydraulic Press Machine is a robust wire forming equipment designed for heavy-duty wire pressing and shaping, suitable for wire diameters up to 16mm. It mainly processes iron and stainless steel wires, and also works with aluminum and copper wires, adapting to various metal wire processing needs. It supports both round wires and flat irons, eliminating the need for multiple machines for different wire forms. To meet specific production requirements, we offer customized functions such as stamping, punching, and welding. With a production speed of 10-30 cycles per minute (depending on processing complexity), it balances precision and efficiency. The machine is equipped with universal molds that do not require replacement for standard pressing tasks, simplifying operation procedures. It comes with a 1-year warranty and a service life of over 10 years under proper maintenance, ensuring long-term operational stability. The multi-language intelligent system allows both button and touchscreen operations, enabling new operators to grasp the operation essentials within 1 hour. Certified with CE, it is widely used in auto and motorcycle parts (for wire component pressing), livestock industry (for animal cage wire pressing), mesh cover industry (for wire mesh frame pressing), supermarket storage racks (for shelf wire pressing), and furniture industry (for wire structure pressing). It does not feature AI, IoT, VR, or laser functions, and is not applicable to aerospace precision components, high-end electronic parts, medical device manufacturing, coils, or steel bars.