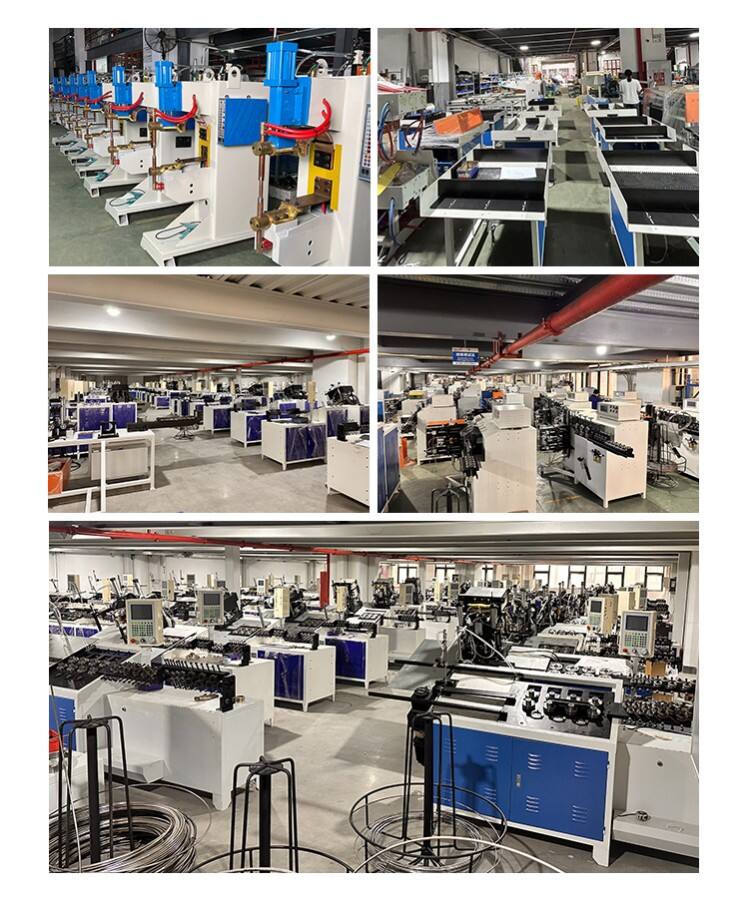

101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-13902844530 [email protected]

101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-13902844530 [email protected]

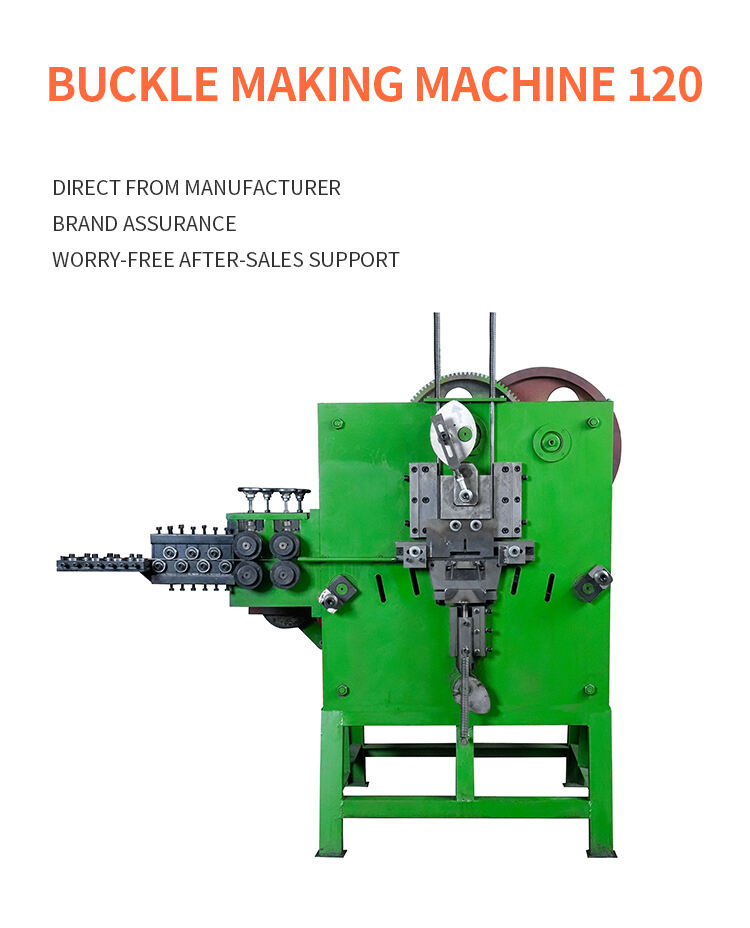

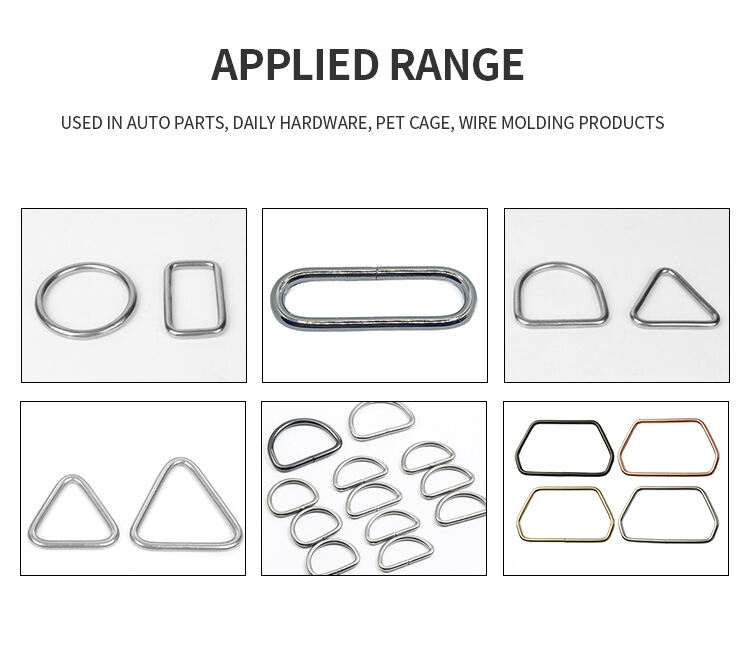

Our Buckle Making Machine is a professional wire forming device designed for efficient buckle production, suitable for wire diameters up to 16mm

| Industry basic attributes | Product custom attributes | ||

| Machine type | Buckle machine | Maximum wire diameter | 3.5 |

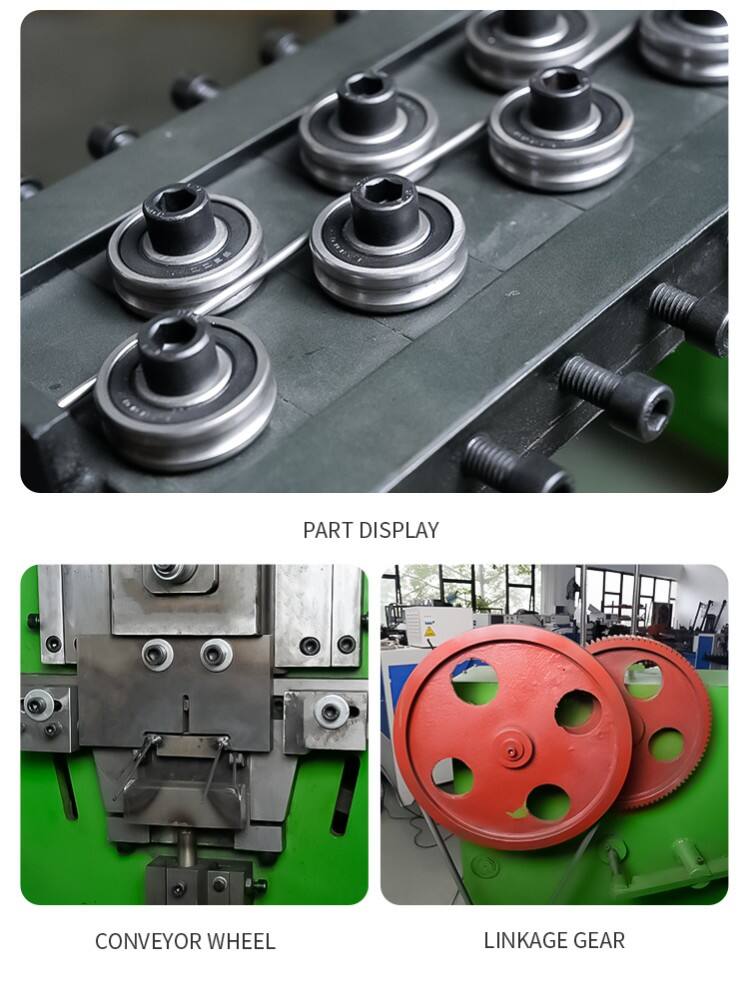

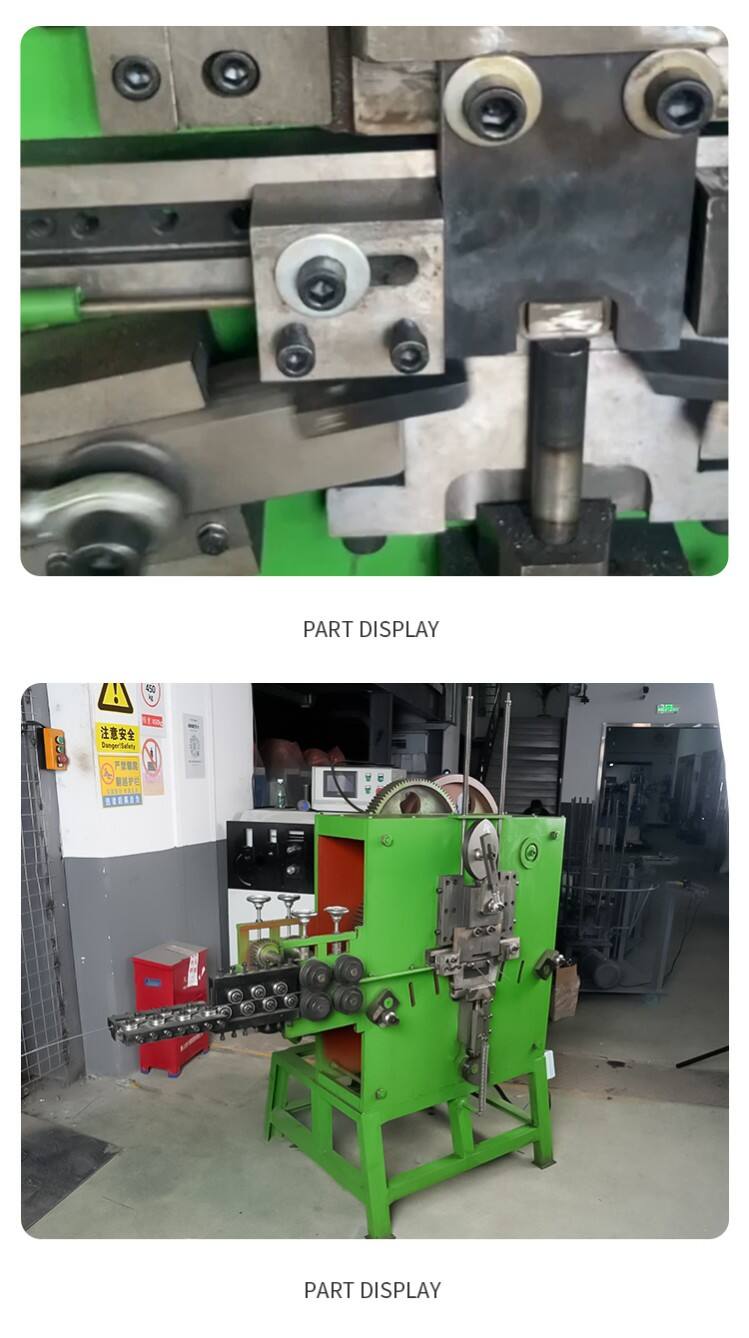

| Core component | Power supply, main motor, gear | Maximum wire feed length | 120mm |

| Processable material | Iron、 steel、 aluminum、 copper、 stainless steel | voltage | 380V |

| Weight (KG) | 250KG | motor power | 0.75KW |

| Video factory inspection | Provided | Is it customizable | Can be customized |

| Mechanical test report | Provided | Suitable Wire Material | Round,Flat,Square,All Kinds of Metal Wires |

| Degree of automation | Automatic | Model | BM-120 |

| Core selling point | Multifunctional、Automatic、Competitive Price | ||

| Logistics attribute | Volume and weight (including logistics packaging) | ||

| Gross weight (KG) : 270KG | Length (CM) : 1350 | Width (CM) : 850 | Height (CM):1400 |

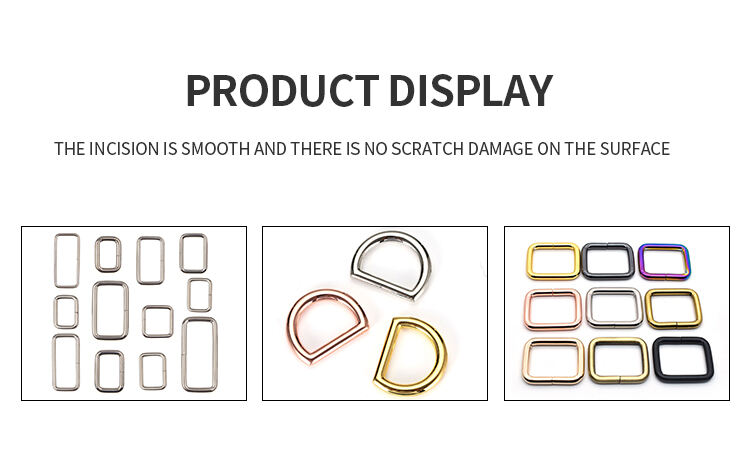

Our Buckle Making Machine is a professional wire forming device designed for efficient buckle production, suitable for wire diameters up to 16mm. It works seamlessly with iron, stainless steel wires as the main materials, and also supports aluminum and copper wires. Notably, it is compatible with both round wires and flat irons, eliminating the need for separate equipment for different wire types. To meet diverse production needs, we offer customized functions such as welding, punching, and stamping. With a stable production speed of 30-75 buckles per minute, it ensures high efficiency for bulk orders. The machine is equipped with universal molds that require no replacement when switching between common buckle specifications, saving valuable production time. It comes with a 1-year warranty and a service life of over 10 years under normal use, providing long-term reliability. The multi-language intelligent system supports both button and touchscreen operations, allowing new operators to master basic functions within 1 hour. Certified with CE, it is widely applied in industries including auto and motorcycle parts (for fastener buckles), kitchen and bathroom hardware (for cabinet buckles), daily-use hardware (for bag buckles), furniture industry (for sofa buckles), and warehouse industry (for storage rack buckles). It does not have AI, IoT, VR, or laser functions, and is not suitable for aerospace precision components, high-end electronic parts, medical device manufacturing, coils, or steel bars.