101, Zgrada 9, Jicheng park za znanstvene inovacije, br. 25, Sanle East Road, zajednica Shunjiang, općina Beijiao, Foshan, Guangdong, Kina +86-18028142339 [email protected]

U skladu s člankom 3. točkom (a) ovog članka, "sistem za upravljanje" znači sustav za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom za upravljanje sustavom

| Osnovne industrijske značajke | Atributovi proizvoda po potrebi | ||

| Napon | 380-440V | Naziv proizvoda | Izravnavajući stroj s letnom makazom |

| Snaga (HP) | 8.1KW | Broj osova | 2 osi |

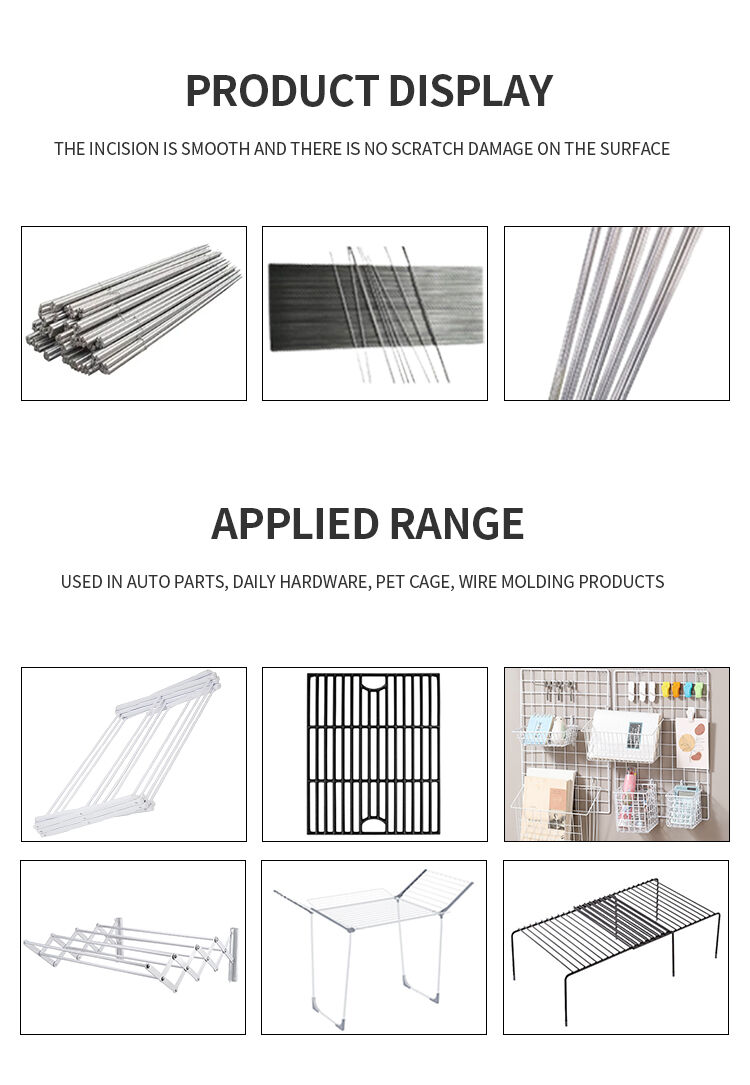

| Brzina opreme | 80-130 m/min | Pogodan materijal žice | Žica od niskougljičnog željeza |

| VRSTA | Ravnala i rezac | Pogodno za promjer žičaka | 2-4mm |

| Primjena | Žica | Odstupanje duljine pri rezanju | ±0.5mm |

| Period garancije | 1 godina | Raspon duljine rezanja | Iznad 80 mm |

| Težina (KG) | 750kg | Žica Snaga motora za hranjenje |

2.3 kW |

| Mjesto podrijetla | Kina | Snaga servo motora za izravnavanje | 3.0KW |

| Povratak | Guangdong | Snaga servomotora rezača | 2.8KW |

| Video o inspekciji u tvornici | Dostavljeno | Broj blokova za izravnavanje | 9 komada |

| Izvješće o mehaničkom testiranju | Dostavljeno | Je li dostupna prilagodba | prilagodljivo |

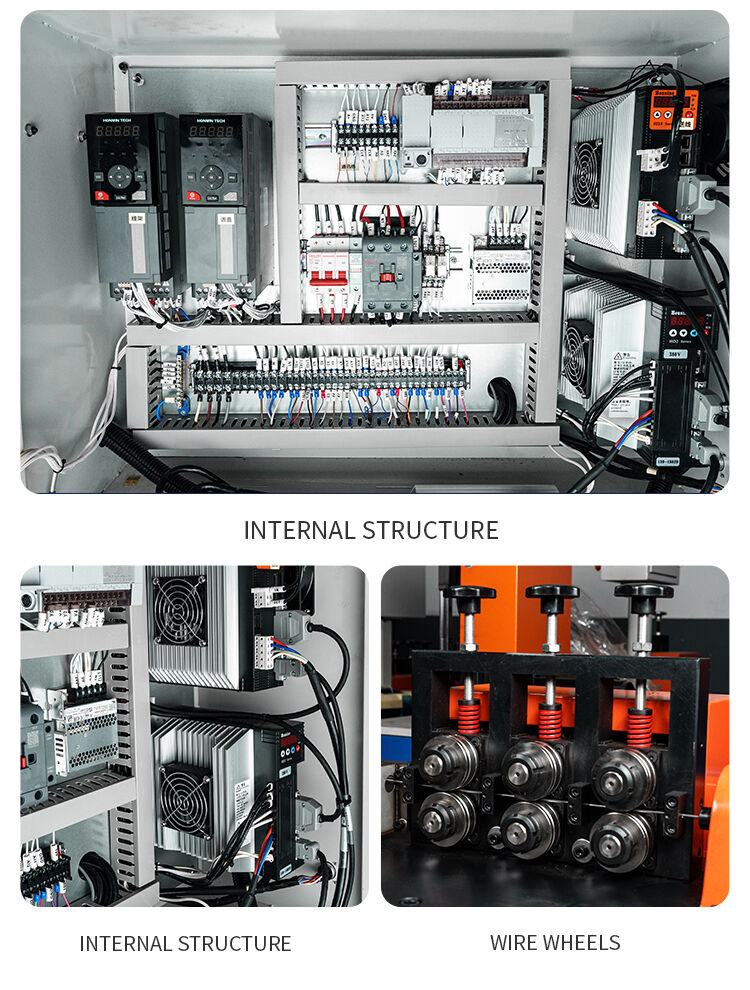

| Osnovne komponente | PLC, Motor, Elektromotor | ||

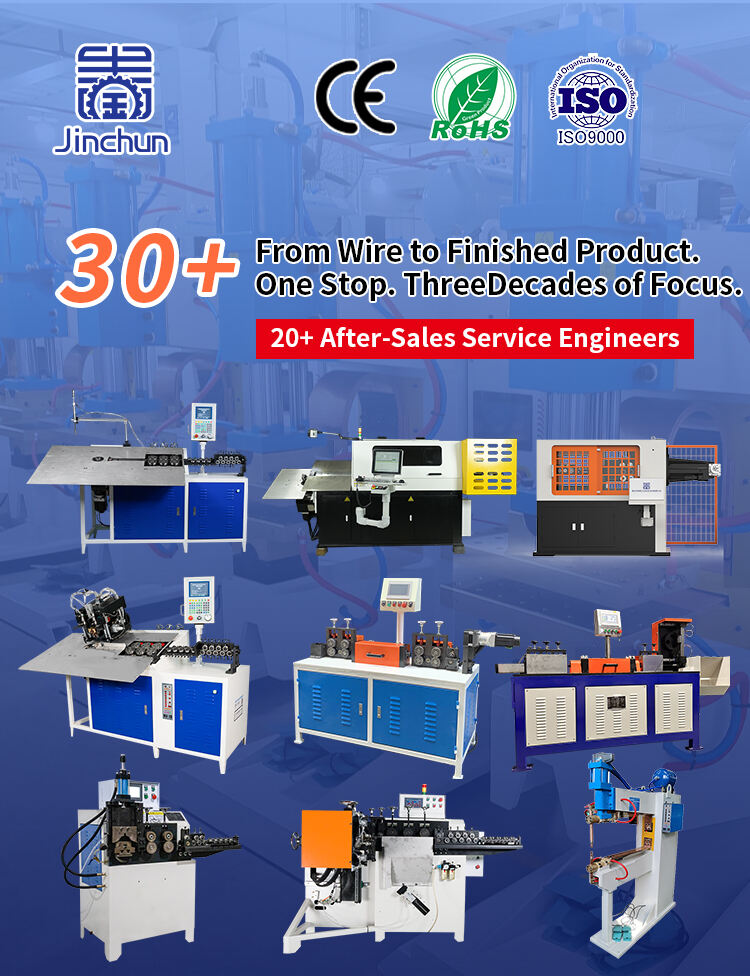

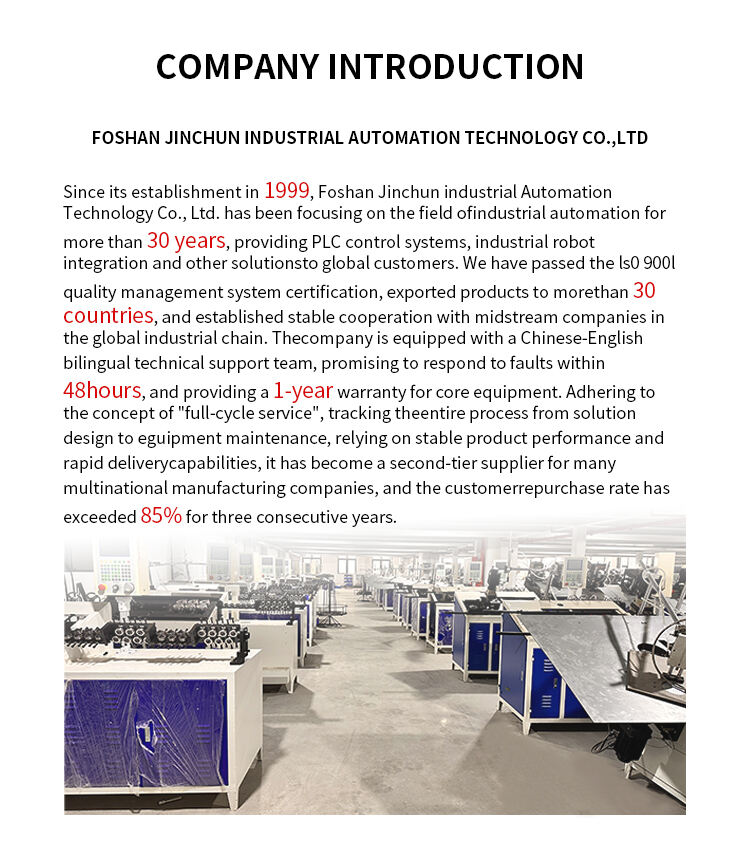

| Marka | JinChun | ||

| U slučaju da je to potrebno, u skladu s člankom 6. stavkom 2. | 2350*750*1550 (mm) | Logistički atributi | Volumen i težina (uključujući pakiranje za logistiku) |

| Glavni tržišni argumenti | Visoka točnost, automatski, jednostavno za uporabu | Bruto težina (kg): 800 kg | U slučaju da je to potrebno, u skladu s člankom 6. stavkom 1. |

| Primjene proizvoda | Ravnala i rezac | Širina (cm): 80 | Visina (cm): 173 |