101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-18028142339 [email protected]

101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-18028142339 [email protected]

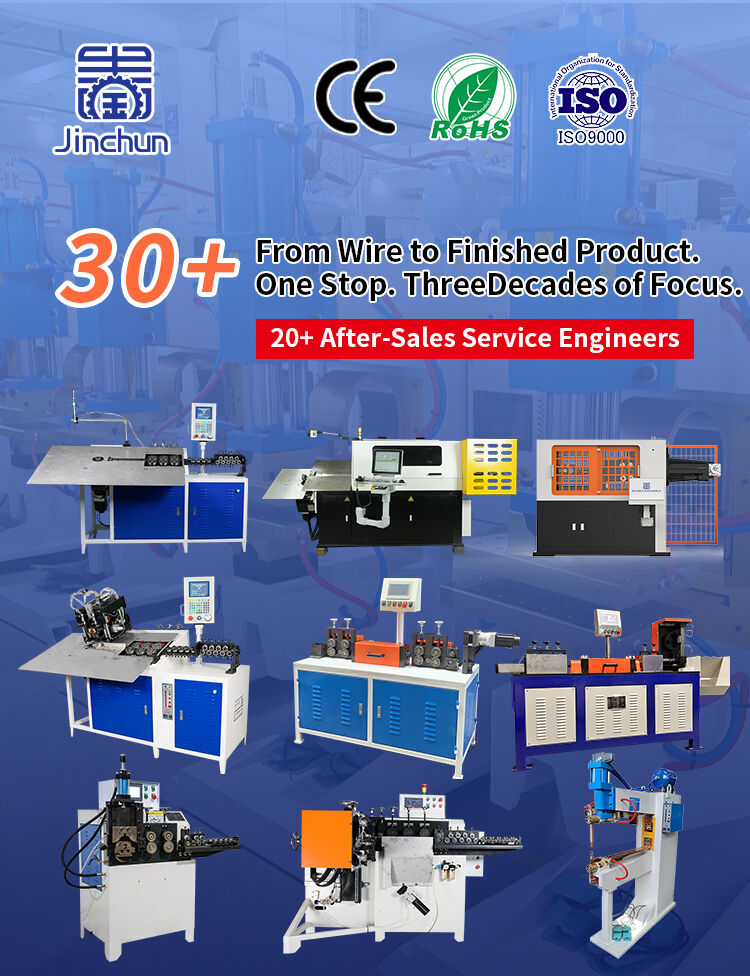

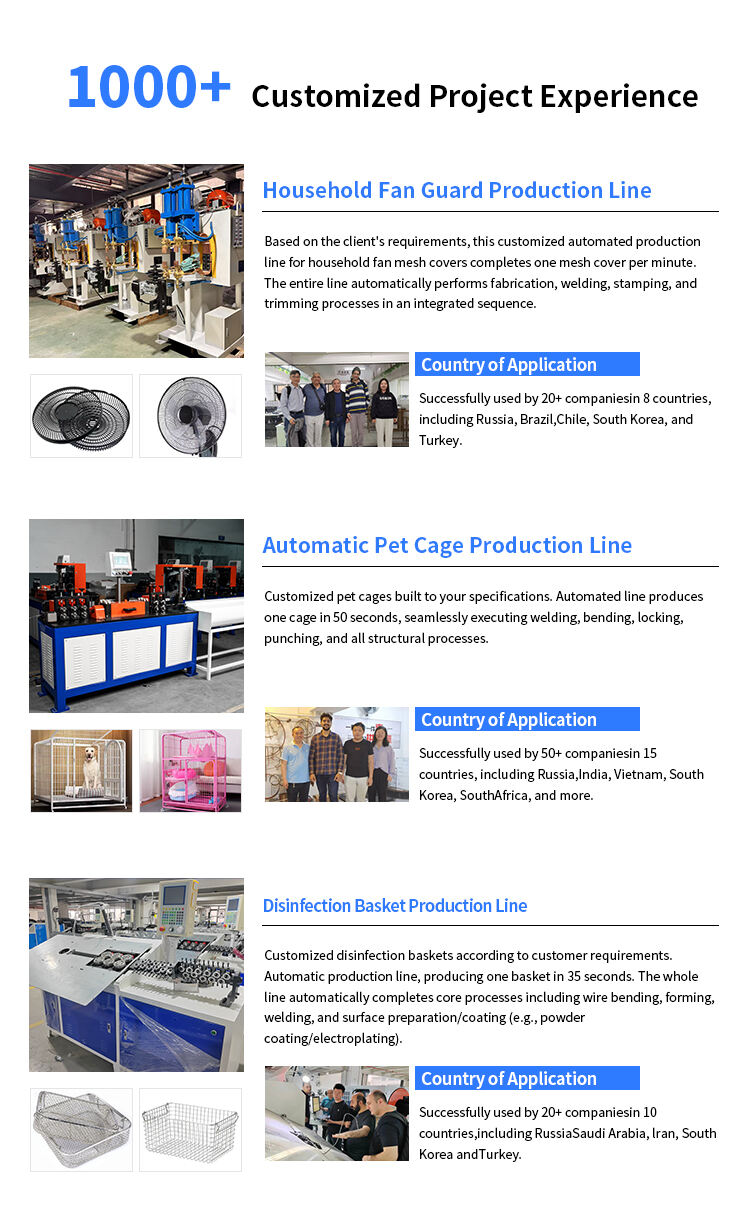

Our Hydraulic Press Machine is a robust wire forming equipment designed for heavy-duty wire pressing and shaping, suitable for wire diameters up to 16mm

| Industry basic attributes | 25T | Product custom attributes | |

| Machine type | Four-column Three-beam Hydraulic Press | Product Name | 25T Hydraulic Press |

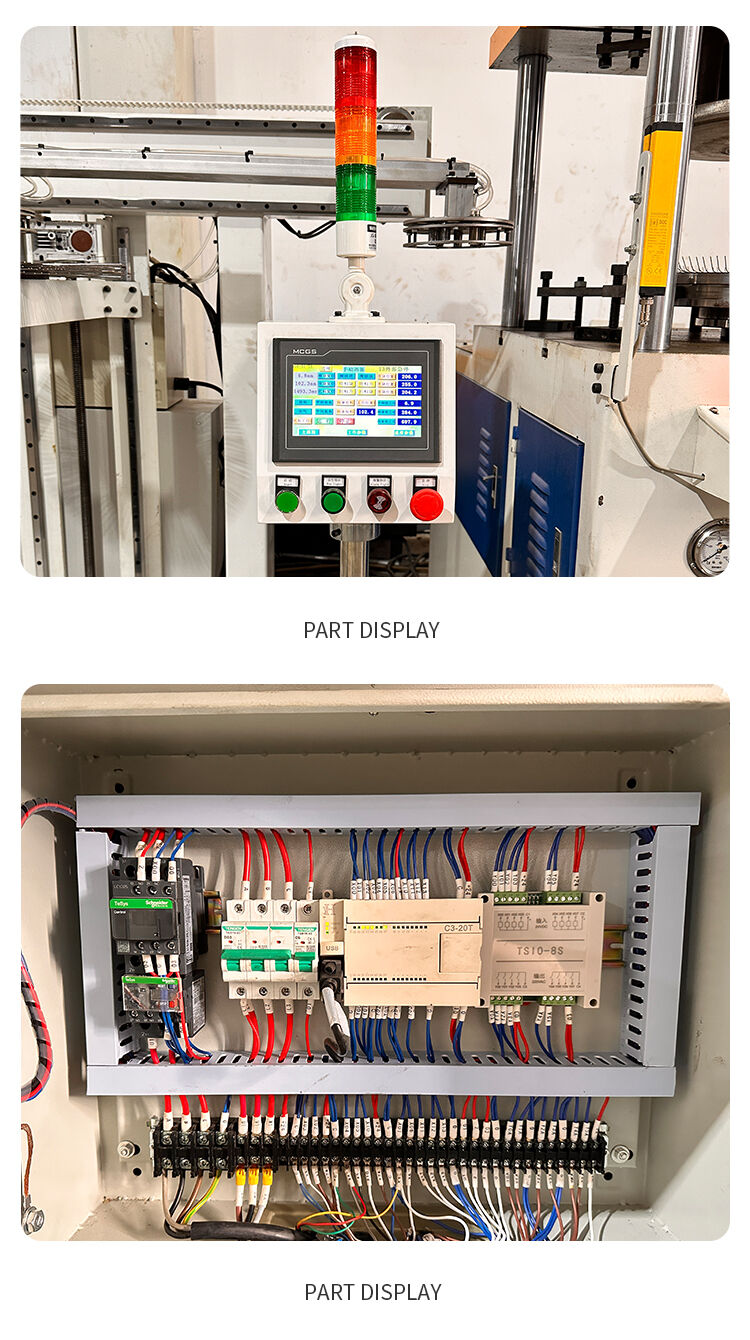

| System | Normal | Current | 30-40A |

| Voltage | 380V | Platform square | 850*850mm |

| Weight (tons) | 1.5T | Speed | 800-900pcs |

| Motor power (KW) | 7.5KW | Protection | Infrared ray device |

| Warranty period | 1 Year | Pressure | 25T |

| Core component | Motor,Pump,Gear,Pressure vessel | Oil Pump | PV2R1-28 |

| Slider stroke (mm) | 350 | Upper cylinder bore diameter | 140mm |

| Top force (KN) | 55 | Upper cylinder pressing stroke | 350mm |

| Return force (KN) | 25 | Lower ejector cylinder bore diameter | 80mm |

| Dimensions (length * width * height) | 1600*1000*2500mm | Hydraulic pump motor power | 7.5KW |

| Model | 25T | Certification | CE |

| Core selling point | Multifunctional、Easy to Operate、High Productivity | Type | Manual Bending Machine |

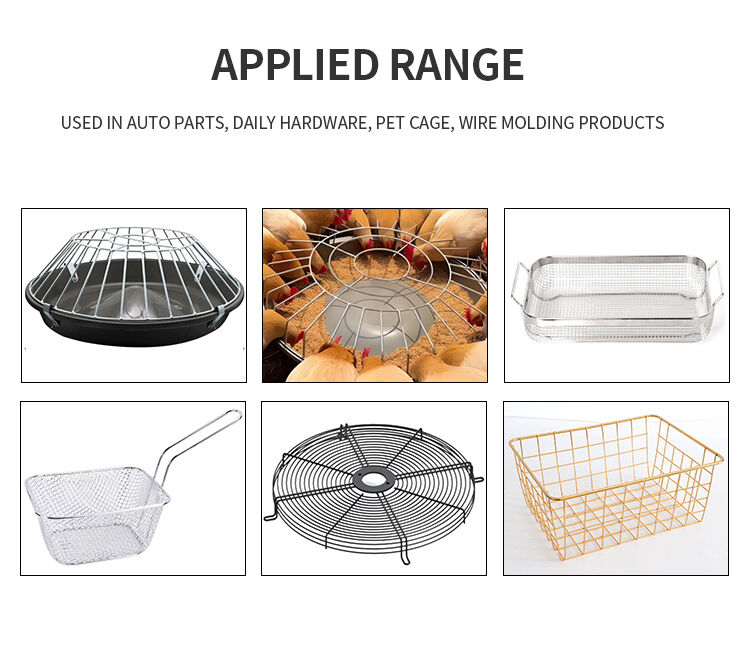

| Mechanical test report | Provided | Suitable for | Fan Guard/Bird Cage/Super Market Cart |

| Video factory inspection | Provided | Transport Package | Sea Worthy Wooden Package or PVC Film for FCL |

| Is it customizable | Can be customized | ||

| Logistics attribute | Volume and weight (including logistics packaging) | ||

| Gross weight (KG) : 1881KG | Length (mm) : 1450 | Width (mm) : 1100 | Height (mm):2200 |

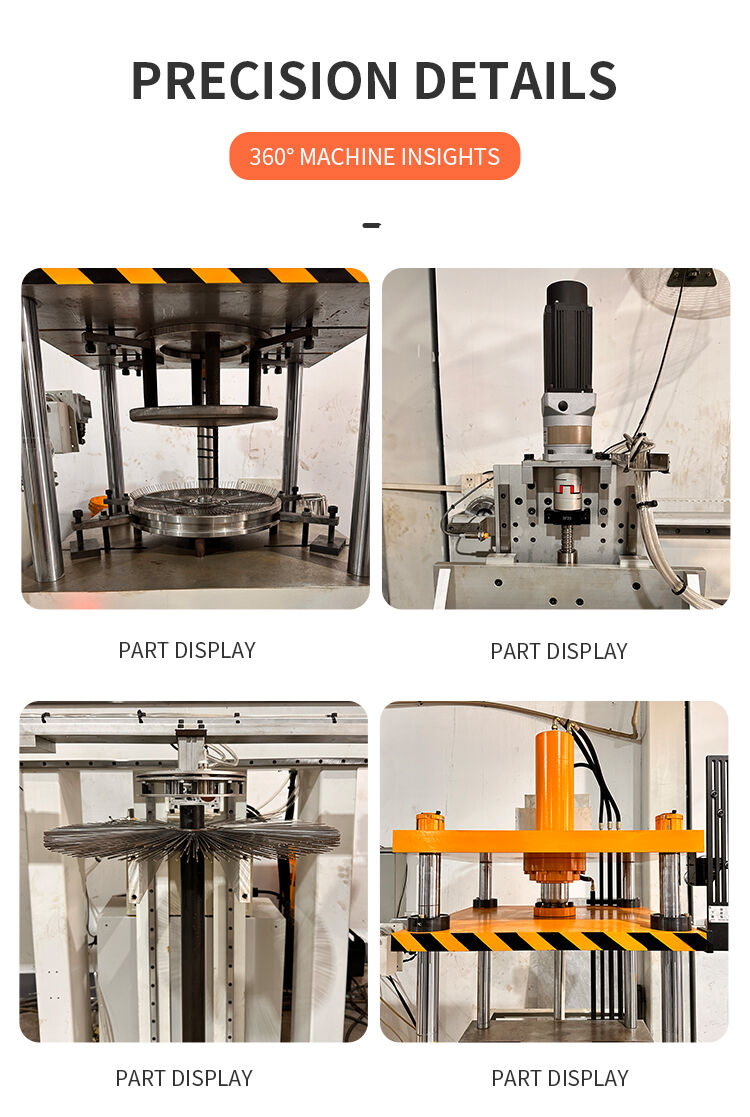

The four-column hydraulic press is an efficient pressure processing equipment designed based on hydraulic transmission principle. Adopting four-column guiding structure with precision guide rails, it ensures stable operation, high rigidity and excellent anti-eccentric load capacity. Precise control of pressure, speed and stroke is achieved through proportional valves and PLC. Multiple safety protections including photoelectric safety gratings and two-hand operation buttons are equipped to ensure operational safety. Modular design makes hydraulic and electrical systems independent for easy maintenance.Robust and durable, the equipment is specially designed for heavy-duty wire pressing & shaping, as well as metal sheet stamping, forming, pressing, straightening, powder forming and other processes. It is applicable to auto manufacturing, hardware processing, home appliance production, mold manufacturing and other fields. With proper maintenance, its service life exceeds 10 years. The multi-language intelligent system supports both button and touchscreen operations, enabling new operators to master proficiently within 1 hour. The entire series has CE certification.