Manufacturing industries rely heavily on precision equipment to maintain product quality and operational efficiency. When it comes to metal processing operations, selecting the right straightening machine becomes crucial for achieving consistent results and meeting production demands. Modern industrial environments require equipment that can handle various wire diameters while maintaining high-speed performance and reliability. Understanding the key factors that influence machine selection will help you make an informed decision that aligns with your specific production requirements and long-term business objectives.

Understanding Material Specifications and Processing Requirements

Wire Diameter Compatibility

The first consideration when selecting equipment involves determining the range of wire diameters your operations will process. Different machines are designed to handle specific diameter ranges, and choosing equipment with appropriate capacity ensures optimal performance. A quality straightening machine should accommodate your current production needs while providing flexibility for future expansion. Consider both the minimum and maximum diameters you'll process regularly, as this directly impacts the machine's roller configuration and adjustment mechanisms.

Most industrial applications require processing wires between 0.5mm to 10mm in diameter, though specialized equipment can handle larger sizes. The roller arrangement and pressure settings must be precisely calibrated for each diameter range to achieve consistent straightening results. Machines with quick-change capabilities allow operators to switch between different wire sizes efficiently, reducing downtime and improving overall productivity.

Material Properties and Characteristics

Different materials exhibit varying degrees of flexibility, tensile strength, and memory characteristics that affect the straightening process. Steel wire requires different processing parameters compared to aluminum, copper, or specialized alloys. Understanding your material's properties helps determine the necessary straightening force and roller configuration. Some materials may require multiple passes or specific temperature conditions to achieve desired straightness tolerances.

Consider the hardness and elasticity of your materials when evaluating machine capabilities. Harder materials typically require more aggressive straightening action, while softer materials need gentler handling to prevent damage. The machine's ability to adjust pressure settings and roller engagement becomes critical for processing diverse material types effectively.

Performance Specifications and Speed Requirements

Processing Speed and Throughput

Production volume requirements directly influence the speed specifications needed from your equipment. High-speed operations demand machines capable of maintaining consistent performance at elevated processing rates. Modern straightening machines can achieve speeds ranging from 10 meters per minute for precision applications to over 100 meters per minute for high-volume production. The straightening machine speed should align with your upstream and downstream equipment capabilities to maintain smooth production flow.

Higher processing speeds require more robust mechanical components and advanced control systems to maintain accuracy. Consider the balance between speed and precision, as extremely high speeds may compromise straightening quality for certain applications. Evaluate your production targets and quality requirements to determine the optimal speed specifications for your operations.

Accuracy and Tolerance Requirements

Straightening accuracy varies significantly across different applications and industries. Precision manufacturing requires tight straightness tolerances, often within 0.1mm per meter or better. Understanding your specific tolerance requirements helps narrow down suitable equipment options. Advanced machines incorporate feedback systems and automated adjustments to maintain consistent accuracy throughout production runs.

Consider both short-term and long-term accuracy requirements, as some applications may have varying tolerance needs. Machines with programmable settings allow operators to store different parameter sets for various products, ensuring consistent quality across multiple production runs. The ability to monitor and adjust straightening parameters in real-time becomes crucial for maintaining tight tolerances.

Machine Design and Construction Features

Roller Configuration and Adjustability

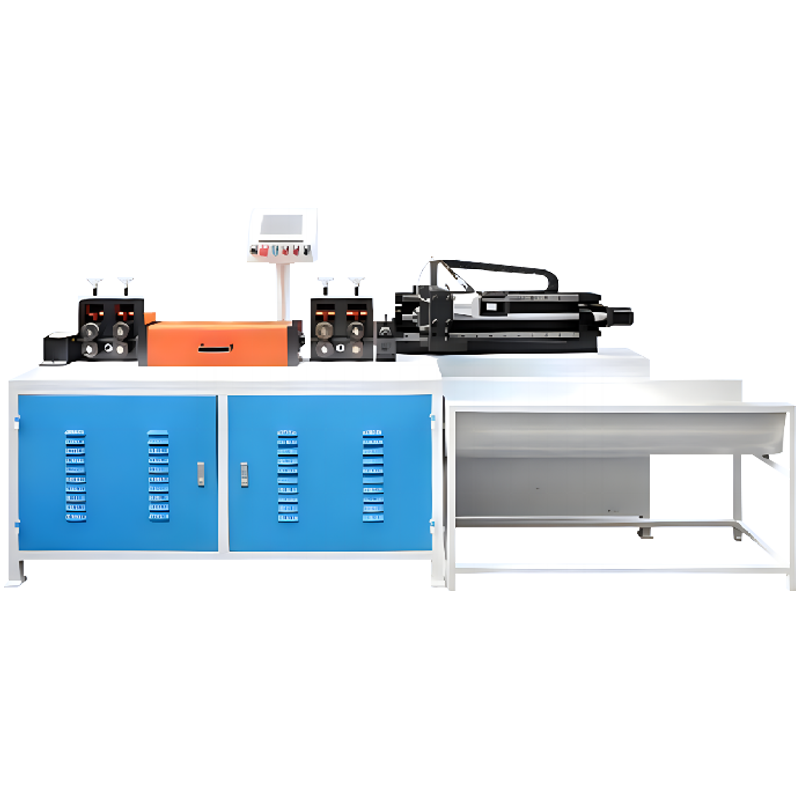

The roller arrangement significantly impacts straightening effectiveness and versatility. Multi-roller systems typically provide better straightening action compared to simple two-roller designs, especially for materials with significant initial curvature. The number of rollers, their positioning, and adjustment mechanisms determine the machine's ability to handle various wire conditions and achieve desired straightness levels.

Adjustable roller systems allow operators to fine-tune the straightening process for different materials and applications. Quick-adjustment mechanisms reduce setup time and improve operational efficiency. Some advanced designs incorporate automated adjustment systems that can adapt to changing wire conditions without manual intervention, ensuring consistent results throughout production runs.

Control Systems and Automation

Modern straightening machines incorporate sophisticated control systems that enhance operational efficiency and consistency. Digital displays provide real-time feedback on processing parameters, allowing operators to monitor performance and make necessary adjustments. Programmable logic controllers enable automated operation sequences and parameter storage for different product configurations.

Advanced automation features include automatic wire detection, parameter adjustment, and quality monitoring systems. These capabilities reduce operator dependency and improve production consistency. Consider the level of automation that aligns with your operational requirements and available skilled personnel. Integration capabilities with existing production management systems can provide additional operational benefits.

Safety and Compliance Considerations

Safety Features and Protection Systems

Workplace safety requirements demand comprehensive protection systems in industrial equipment. Emergency stop mechanisms, safety guards, and interlock systems prevent accidents and protect operators from potential hazards. Proper guarding around moving components ensures safe operation while maintaining accessibility for maintenance and adjustments.

Consider machines with built-in safety monitoring systems that can detect abnormal operating conditions and automatically shut down operations when necessary. Warning systems and visual indicators help operators identify potential issues before they become safety hazards. Training requirements and safety documentation should be evaluated as part of the overall equipment selection process.

Regulatory Compliance and Certifications

Industrial equipment must comply with relevant safety and performance standards in your operating region. CE certification ensures compliance with European safety directives, while other certifications may be required for specific markets or applications. Verify that your chosen equipment meets all applicable regulatory requirements before making final purchasing decisions.

Documentation and compliance certificates provide assurance of equipment quality and safety standards. Regular inspection and maintenance requirements should be clearly defined to maintain compliance throughout the equipment's operational life. Consider the availability of certified service technicians and spare parts for ongoing compliance maintenance.

Economic Factors and Return on Investment

Initial Investment and Operating Costs

Equipment cost extends beyond the initial purchase price to include installation, training, and ongoing operational expenses. Higher-quality machines typically command premium prices but often provide better long-term value through improved reliability and performance. Evaluate the total cost of ownership, including energy consumption, maintenance requirements, and expected service life.

Consider financing options and payment terms that align with your budget constraints and cash flow requirements. Some manufacturers offer leasing arrangements or performance-based contracts that can help manage initial investment costs. Factor in potential productivity improvements and quality enhancements when calculating the return on investment for different equipment options.

Maintenance Requirements and Support

Regular maintenance ensures optimal performance and extends equipment service life. Evaluate the complexity and frequency of required maintenance procedures, as well as the availability of replacement parts and service support. Machines with simplified maintenance procedures reduce operational disruptions and lower long-term costs.

Consider the manufacturer's service network and technical support capabilities in your geographic region. Rapid response times for service calls and parts availability become crucial for minimizing production downtime. Training programs for your maintenance staff can help reduce dependency on external service providers and improve overall equipment reliability.

FAQ

What wire diameters can modern straightening machines typically handle

Most industrial straightening machines are designed to process wire diameters ranging from 0.5mm to 10mm, though specialized equipment can handle sizes up to 25mm or larger. The specific diameter range depends on the machine's roller configuration and mechanical design. Multi-diameter machines offer quick-change capabilities to accommodate various wire sizes within their specified range, making them ideal for operations processing multiple product types.

How do I determine the appropriate processing speed for my application

Processing speed selection depends on your production volume requirements, quality tolerances, and material characteristics. High-volume operations may benefit from speeds exceeding 50 meters per minute, while precision applications requiring tight tolerances might operate at lower speeds for better control. Consider your upstream and downstream equipment capabilities to ensure balanced production flow and avoid bottlenecks in the manufacturing process.

What maintenance procedures are typically required for straightening machines

Regular maintenance includes roller inspection and cleaning, lubrication of moving components, calibration verification, and wear part replacement. Most machines require daily cleaning and weekly lubrication, with more comprehensive inspections performed monthly or quarterly. Proper maintenance schedules help prevent unexpected downtime and ensure consistent straightening performance throughout the equipment's operational life.

How important is CE certification for industrial straightening equipment

CE certification ensures compliance with European safety and performance directives, making it essential for operations in European markets and increasingly important globally. Certified equipment meets strict safety standards, provides operator protection, and includes proper documentation for regulatory compliance. Even outside Europe, CE certification often indicates higher build quality and adherence to international safety standards.