101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-18028142339 [email protected]

101, Building 9, Jicheng Science And Technology Innovation Park, No. 25, Sanle East Road, Shunjiang Community, Beijiao Town, Foshan, Guangdong, China +86-18028142339 [email protected]

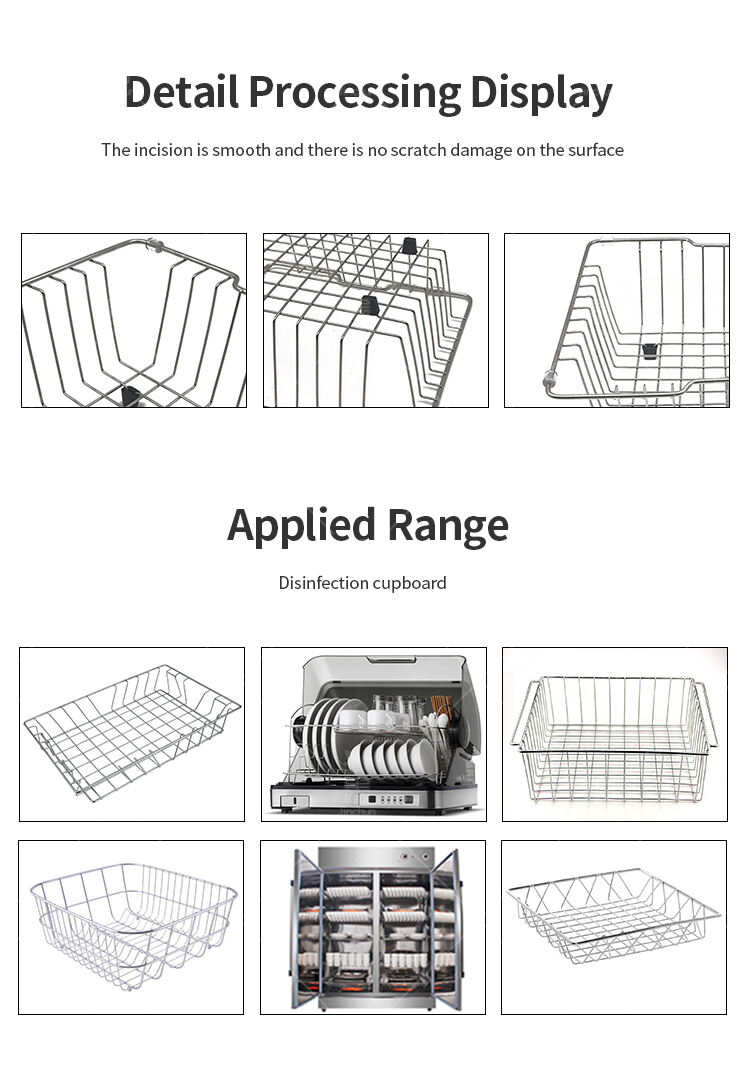

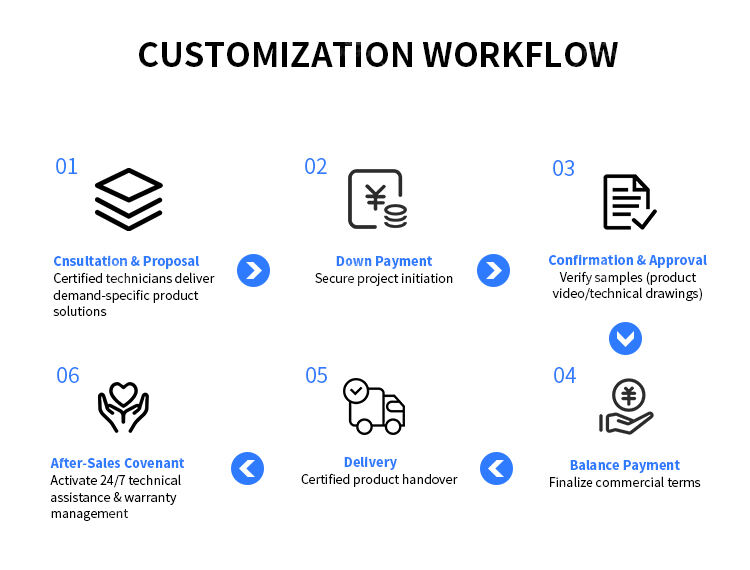

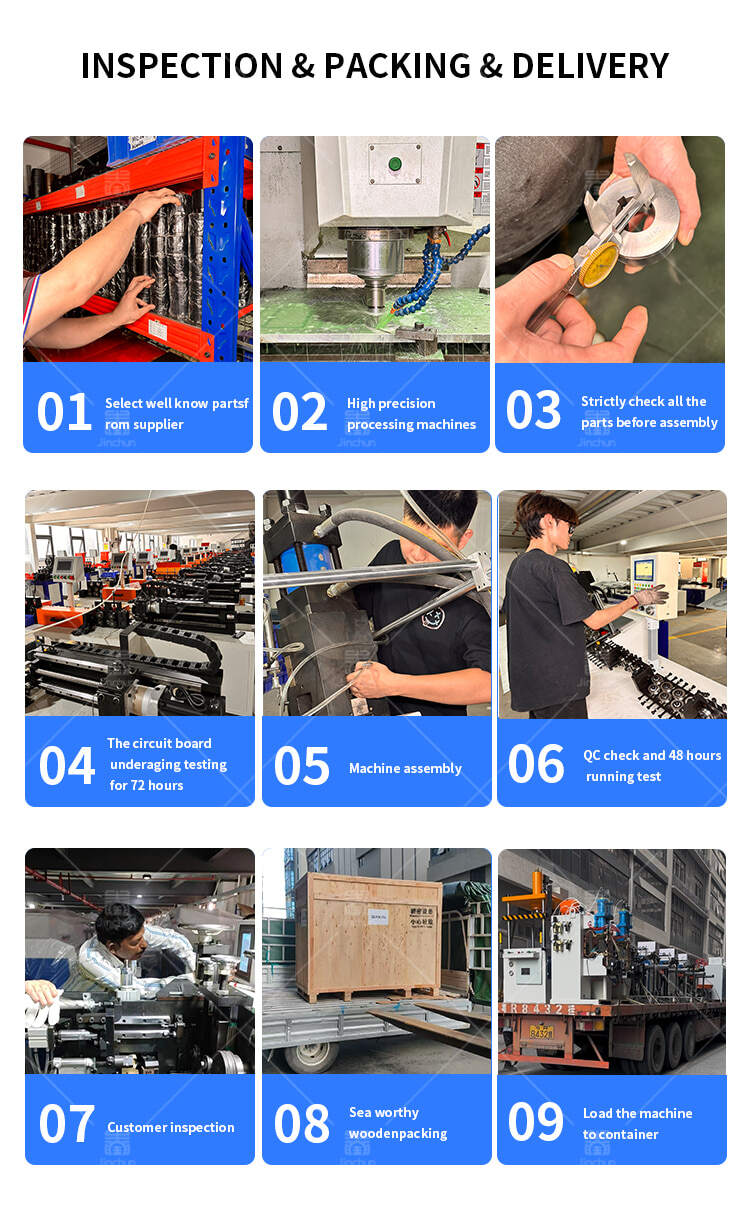

Jinchun delivers integrated sterilized cupboard production lines comprising 9 specialized machines. With over 30 years of industrial automation expertise, we provide high-productivity solutions characterized by micron-level precision and minimal maintenance requirements. Our support system includes 20+ dedicated engineers delivering lifelong technical assistance to disinfect cabinet manufacturers globally.

All equipment exceeds 10-year service life with <3% annual failure rate. We guarantee under 2-hour average response time for after-sales support, backed by 1-year warranty. Each machine undergoes rigorous pre-shipment quality control and carries CE certification, ensuring reliable performance and compliance with international standards.

One-SSterilized cupboard production line:

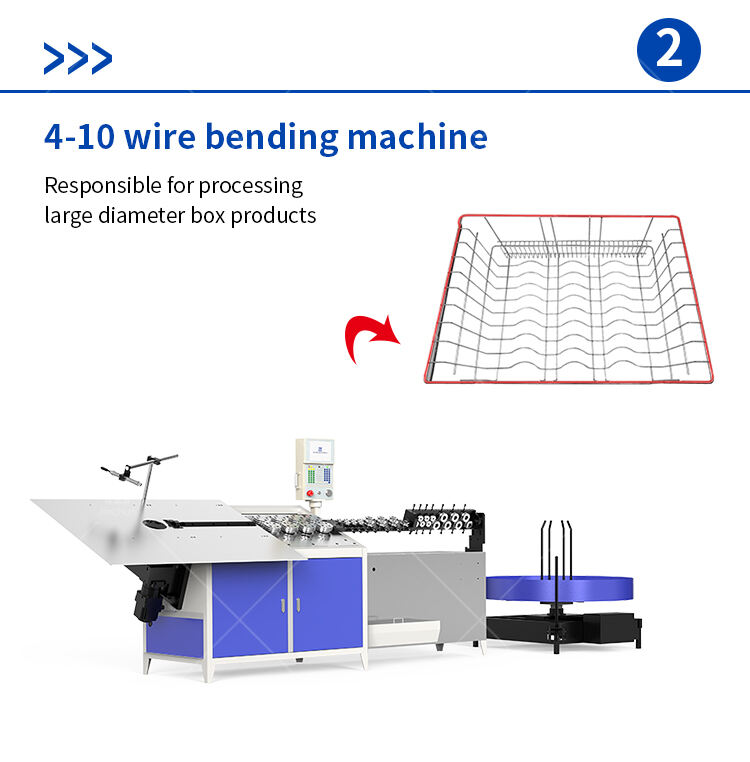

2-6 wire bending machine(Responsible for shaping the bottom mesh shape)→ 4-10 wire bending machine(Responsible for processinglarge diameter box products)→ Wire straightening machine(Cut off the straight strip afteradjusting the required length)→ Rowing welding machine(Responsible for welding the bottom mesh)→ Spot welding machine(Responsible forspot welding and repair welding)→ Rowing welding machine(Responsible for the side mesh)→ Edge trimming machine(Clean the burrs on the mesh)→ Manual bending machine(Bend the wire into a half frame shape)→ Touch welding machine(Weld the two ends of the box together)

Manufacturers no longer need to source multiple machines separately—we deliver a fully-equipped, ready-to-operate production line.